AirBorne Microlight /Trike Wing Nose Channel Mandatory Service Bulletins

Part 1: Date 21st November 2003: We are currently investigating cracking in the area of the stainless steel nose channel on some Airborne wings. Until we have fully investigated this issue, we recommend that owners/pilots of all Airborne microlight/trike wings inspect the nose channel before flying.

It is necessary to remove the nose channel from the wing to enable proper inspection. This is a simple job and can be done by removing the 2 bolts that attach the nose channel to the keel through the nose plates.

A tip for removal: Once the nyloc nuts are removed the bolts can be pushed through using same diameter bolts, this will help to keep the keel and plates lined up for reattaching the channel later. Simply push the bolts back through the other way when reinstalling the channel.

Once the nose channel has been removed check for any cracking around the holes on the back side where the channel attaches to the wing. If any cracking is found do not fly the wing until the part has been replaced.

Replacement nose channels are available from the factory. Please state the serial number of the wing when ordering parts. The number is located between the top of the control frame.

Please pass on this information to any other Airborne pilots that you know of. An update of this advisory will be published on the web site once the investigation is complete.

Part 2: Date 25th November 2003: Our engineers have been studying

the reports of cracking that we have received. Analysis and tests have confirmed

that this cracking is caused by fatigue due to local stress concentration in

the region adjacent to the front mounting bolt. We have simulated, by test,

the complete failure of the nose catch in this region. This testing shows that,

even if the front bolt hole failed, the rear bolt and the nose catch channel

alone are capable of supporting a load of at least 8g.

We believe that fatigue cracks in this area are not acceptable and our engineers

are evaluating alternative designs to eliminate this problem. Another update

will be published as part of this AD when this evaluation has been completed.

In the meantime an inspection of the nose catch channel is essential and any

cracking should render the aircraft unusable until such time as the part is

replaced.

Part 3 and Final: Date 06th February 2004: We now have a 3 mm

guage replacement nose channel available.We also have modified nose pip pins

available. Regular inspection of existing nose channels by complete removal

or replacement with the new 3mm guage channel is essential. The new channel

will allow for easier nose pip pin assembly or removal, simply because of the

heavier guage.Once the new channel is installed then inspection as per the

maintenance manual is still required.

Orders can be placed directly to the factory for the nose channel and the modified

pip pin. The part will be invoiced with customer details recorded with the

serial number of the wing the nose channel is to be used on. Customers returning

their old nose channel and pip pin will be refunded for the invoice amount

of the new part. This is an incentive to return your nose channel to the factory

and will allow us to check the condition of existing channels for our own research.

Note: A kit will be supplied with a drawing and instructions on replacing the

nose channel. It is recommended to also replace the nyloc nuts if they have

been previously removed. Nylocs should not be installed more than two times

because of wear on the nylon.

The parts can be ordered from the factory by email or telephone or through

your dealer. We will require your name address, contact phone number and the

model and serial number of your wing and the amount of hours flown on the wing.

You will also need to supply your credit card details for payment. Payment

will be refunded once your return your old nose channel.

Description: Nose Channel Part No: 106278

US owners: $34 includes overseas postage

Australian Inc GST $42 includes postage

Export Aud$47.00 includes postage

Order CHECKLIST if emailing, phoning or faxing a request for a replacement nose channel. Please provide the following details in your correspondance. These details need to be recorded on the invoice.

1/ Wing type and serial number

2/ Amount of hours flown on the wing

3/ Your name address and contact phone number

4/ Your credit card details

To get the credit you are required to return:

1/ Your wings old nose chanel

2/ The pip pin without the cap

3/ A copy of the invoice

|

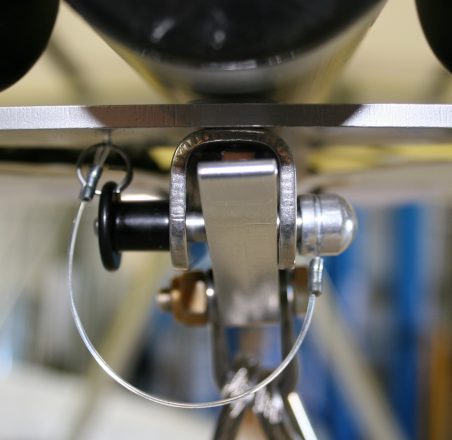

Stainless steel nose channel where front wires attach

Note: the extra attachement on the photo is simply a string that holds

identification tabs on new wings. |

|

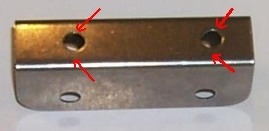

Two views of the stainless steel nose

channel after removal from the wing |

|

| Back view nose channel |

| Carefully inspect the holes on the back side of the nose channel for cracking around the holes themselves. |

It is simple to check if your wing has the latest type of nose channel. See the picture below. The new nose channel is made from 3mm thick stainless steel as opposed to the old channel which was made from thinner 0.85mm thick stainless steel. You can use a rule to measure the thickness of your nose channel if you are unsure, or simply ask one of our dealers. |

|